pump and motor having mobile chamber

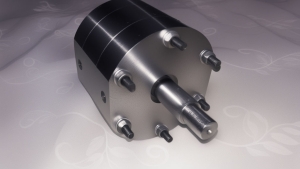

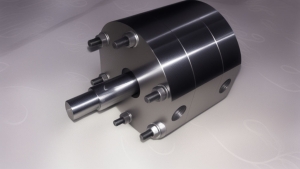

Pre-production sample, variable displacement pump

Description of a Pump and Motor with Mobile Chambers

**Title**: **Hydraulic Pump and Motor Having Mobile Chambers**

**Abstract**:

The invention relates to a hydraulic pump and motor system featuring mobile chambers, designed to enhance efficiency and prevent cavitation. This innovative system combines the functionalities of a pump and a motor within a single integrated unit, offering improved performance, reduced energy consumption, and greater adaptability to various operational requirements.

**Technical Field**:

This invention pertains to the field of fluid dynamics, specifically to hydraulic pumps and motors used in industrial, automotive, and other applications requiring fluid transfer and mechanical power conversion.

**Background**:

Conventional hydraulic pump systems often face limitations such as cavitation, inefficiency, and mechanical wear. Cavitation occurs when the fluid provided to the pump is insufficient, causing the formation and collapse of vapor bubbles, leading to damage. Existing solutions involve pressurizing the pump intake or using auxiliary pumps, but these approaches are not entirely effective in eliminating cavitation and its associated costs.

**Summary of the Invention**:

The primary objective of this invention is to provide a hydraulic pump and motor system with mobile chambers that significantly improves fluid handling efficiency and system adaptability while preventing cavitation. The mobile chamber design allows for dynamic adjustments in chamber volume, optimizing fluid transfer rates and mechanical power output based on real-time operational demands.

**Detailed Description**:

1. **Construction**:

– **Mobile Chambers**: The core innovation of this system is the mobile chambers, which can adjust their volume dynamically during operation. The chambers’ mobility is facilitated by T-shaped components and sliders that ensure fluid does not contact the shaft, reducing wear and corrosion.

– **Pump Mechanism**: The pump component utilizes the mobile chambers to draw in and discharge fluid efficiently. The adjustable chamber volume allows for precise control over fluid intake and output, reducing energy consumption and improving overall performance.

– **Motor Mechanism**: The motor component leverages the mobile chambers to convert fluid pressure into mechanical power. The ability to vary chamber volume enhances the motor’s adaptability to different load conditions, optimizing power output and efficiency.

2. **Operational Advantages**:

– **Enhanced Efficiency**: The mobile chamber design minimizes energy losses by optimizing fluid flow and pressure throughout the pump and motor operation.

– **Adaptability**: The system’s ability to adjust chamber volume in real-time allows it to adapt to varying operational conditions, making it suitable for a wide range of applications.

– **Compact Design**: Integrating the pump and motor functionalities into a single unit with mobile chambers reduces the overall system size, making it ideal for applications with space constraints.

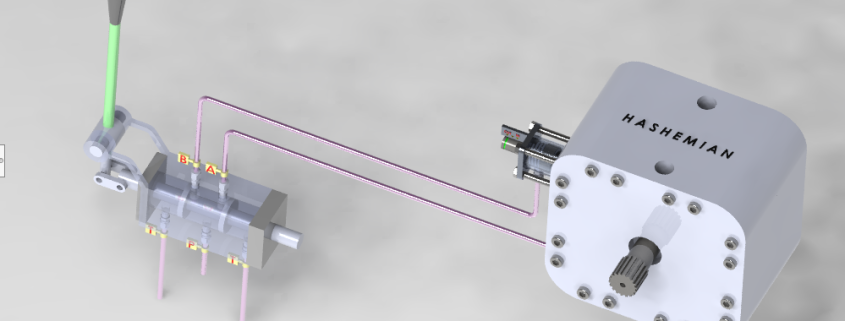

3. **Control System**:

– The invention includes an advanced control system managed by an Electronic Control Unit (ECU). The ECU monitors operational parameters such as fluid pressure, flow rate, and mechanical load, adjusting the mobile chamber volume accordingly to optimize performance.

4. **Applications**:

– **Industrial**: Suitable for fluid transfer in manufacturing processes, hydraulic systems, and chemical processing.

– **Automotive**: Ideal for use in hydraulic braking systems, power steering, and fuel injection systems.

– **Aerospace**: Can be applied in aircraft hydraulic systems for improved efficiency and reliability.

– **Marine**: Useful in marine propulsion and fluid handling systems, providing robust and adaptable performance in harsh environments.

**Claims**:

1. A hydraulic pump and motor system comprising:

– A first inlet duct arranged on a front cover;

– A second inlet duct arranged on a rear cover;

– A plurality of movable chambers, each comprising a male protruding part and a female recessed slot;

– A shaft connected to the plurality of movable chambers, wherein rotation of the shaft causes the movement of the chambers, resulting in fluid suction and propulsion operations.

2. The system of claim 1, wherein the movable chambers are configured to neutralize radial and axial forces.

3. The system of claim 1, further comprising T-shaped components and sliders to attach the chambers to the shaft, preventing fluid contact with the shaft.

4. The system of claim 1, wherein the chambers’ design and the placement of inlet and outlet ducts optimize suction efficacy and reduce cavitation.

5. The system of claim 1, designed to operate in both directions and under various pressure and volume ranges.

**International Patent Classification**:

– F04B 43/00 (Pumps)

– F04D 29/00 (Pumping Systems)

– F16H 39/00 (Fluid Motor and Pump Combinations)

**PCT Filing**:

This invention has been filed under the Patent Cooperation Treaty (PCT) with the application number PCT/IB2022/059381. This filing facilitates international protection, allowing the invention to be patented in multiple jurisdictions, ensuring its broad application and utilization across diverse global markets.

By integrating mobile chambers, this hydraulic pump and motor system represents a significant advancement in fluid dynamics technology, providing enhanced efficiency, flexibility, and performance in a compact and adaptable package.

Leave a Reply

Want to join the discussion?Feel free to contribute!